| Parameter | Unit |

| X axis travel | mm |

| Y axis travel | mm |

| Z axis travel | mm |

| Table size | mm |

| Working table load | kg |

| Spindle taper | |

| Spindle motor | kW |

| Spindle speed | rpm |

| Distance from spindle nose to table top | mm |

| Tool magazine capacity | |

| Max tool diameter | mm |

| Tool length | mm |

| Tool weight | kg |

| Machine weight | kg |

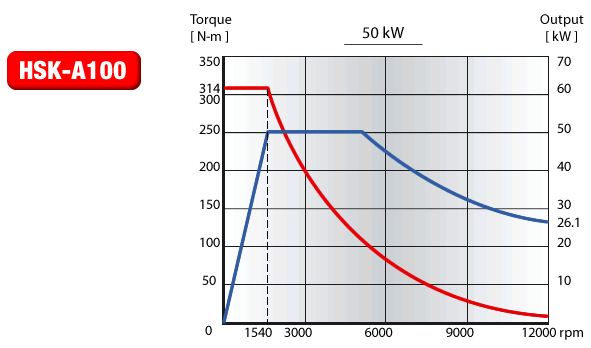

Mega5 P3025 3000 3200 1000 3020x2400 12000 HSK-A100 50/40 10-12000 200-1200 40 Ø140 350 15 39000

POWERFULL HIGH SPEED SPINDLE

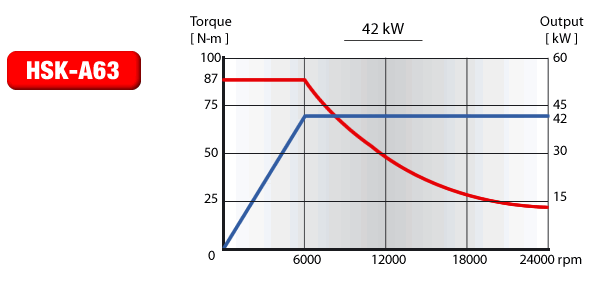

Whole series of MEGA5 can select HSK-A100 high torque spindle for heavy cutting or HSK-A63 24,000 rpm high speed spindle. MEGA5 series is not only suitable for high speed high accuracy cutting but also suitable for heavy cutting at low rpm range.

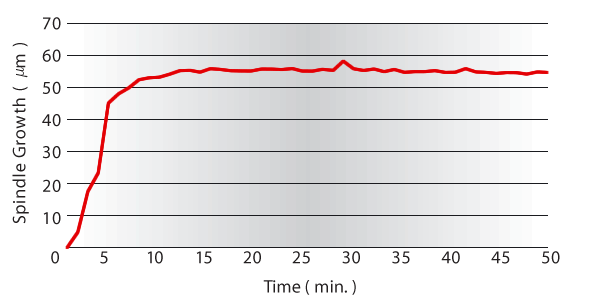

Spindle Growth Chart

High accuracy built-in motorized spindle thermal expansion reaches stable state within 10 minutes from machine cold start. Even under long time continuous machining, the spindle thermal expansion variation is still within 0.01 mm range.

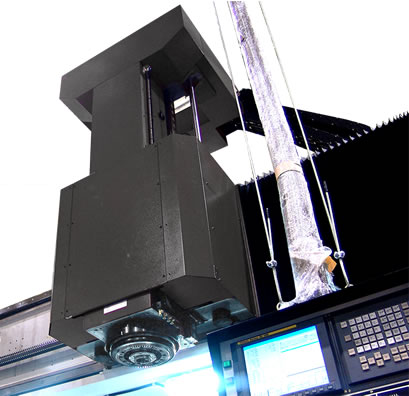

DUAL AXIS UNIVERSAL MILLING HEAD

Modular design, symmetric fork structure, DC motor installed on each side of fork structure, the spindle motor is installed in the center of rotary axis. Integrated direct-driven motor along with hydraulic clamping system in B, C axis; if compared with traditional worm gear design provides multiple benefits like higher accuracy, zero backlash and low wear out.

High rigidity cross roller bearings ( diameter B-axis : 150 mm / C-axis : 320 mm ) can withstand higher axial load, radial load and coupled load in both direction.

Hydraulic clamping system effectively locked both rotational axes to support heavy cutting at fixed angle.

B, C-axis accuracy and efficiency is effectively enhanced via high resolution absolute encoder.

Z-axis extra large size linear guide ways along with larger saddle and high rigidity box structure headstock provides best cutting rigidity.

Unique head design which the main spindle, spindle motor, ball screw and hydraulic counter weight cylinders are symmetrically placed. Hereby preventing thermal distortion and minimizing deflection. Assuring accuracy and heavy cutting capability.

Moving table design with very high machine stability, cutting rigidity and machining capability, suitable for all kinds of material heavy cutting requirement.